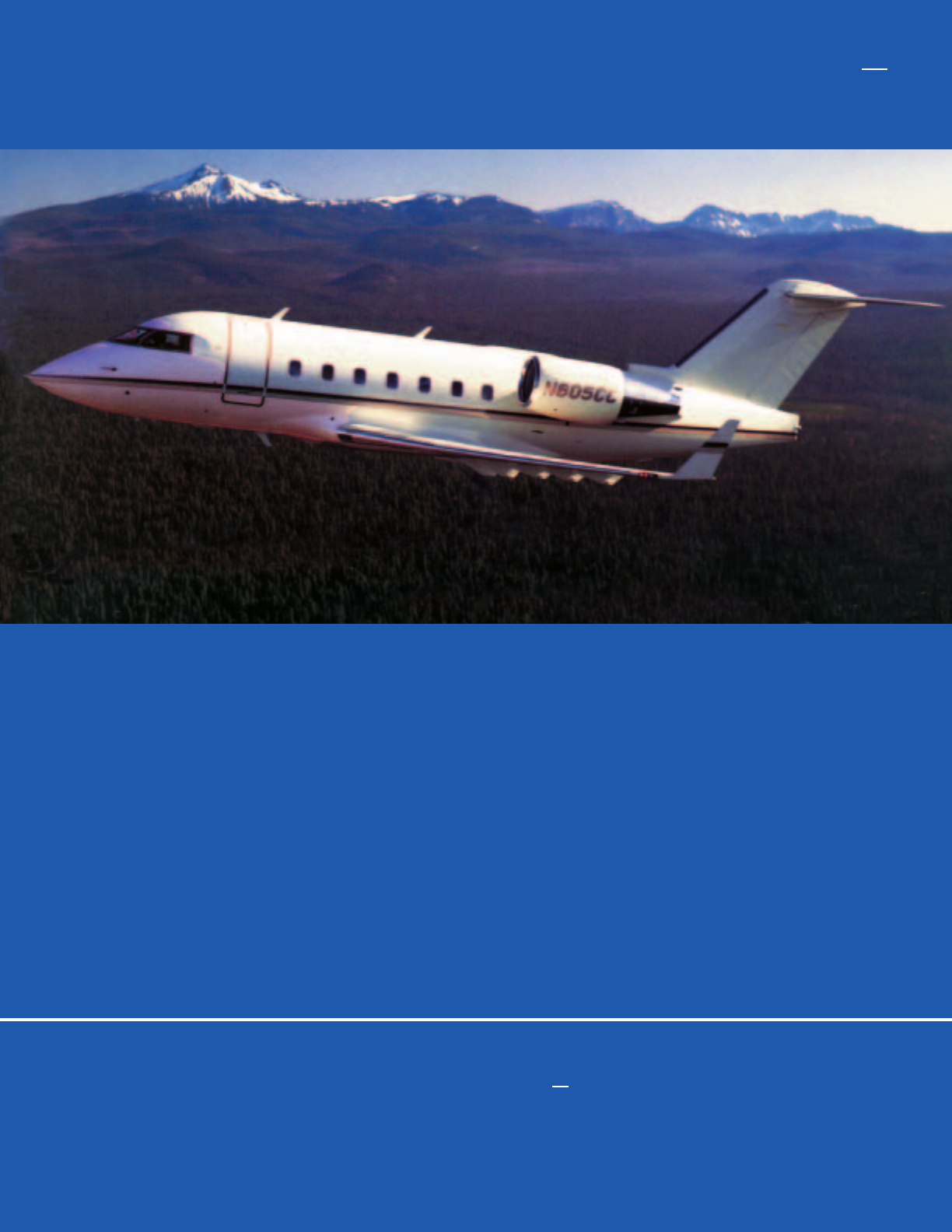

CL 601-3A/R PILOT TRAINING MANUAL VOLUME 2

Record of Revision No. .01

This is a revision of the CL 601-3A/R Volume 2 Pilot Training Manual.

The portion of the text or figure affected by the current revision is indicated by a solid vertical

line in the margin. A vertical line adjacent to blank space means that material has been delet-

ed. In addition, each revised page is marked “Revision .01” in the lower left or right corner.

The changes made in this revision will be further explained at the appropriate time in the

training course.

FlightSafety

international

COURSEWARE SUPPORT—HURST 8900 Trinity Blvd. Hurst, Texas 76053 (817) 276-7500 Fax (817) 276-7501

the best safety device in any aircraft is a well-trained crew...

9555 Ryan Avenue

Dorval, Quebec, Canada H9P 1A2

(800) 573-4025

www. flightsafety.com

Canadair

CHALLENGER CL-601-3A/R

MODEL CL-600-2B16

PILOT TRAINING MANUAL

VOLUME 2

AIRCRAFT SYSTEMS

FlightSafety Canada

Ltee

Ltd.

'

FlightSafety Canada

Ltee

Ltd.

'

Courses for the Canadair Challenger Model CL-600-2B16 and other Canadair

aircraft are taught at:

FlightSafety Canada Ltd.

Montreal Learning Center

9555 Ryan Avenue

Dor val, Quebec

Canada H9P 1A2

(800) 573-4025 • Fax (514) 631-2263

FlightSafety Texas

Houston Learning Center

7525 Fauna Street

Houston, TX 77061

(800) 927-1521 • Fax (713) 644-2118

FlightSafety International

Tucson Learning Center

1071 E. Aero Park Blvd.

Tucson, AZ 85706

(800) 203-5627 • Fax (602) 889-9619

Copyright © 2003 by FlightSafety International, Inc. All rights

reserved. Printed in the United States of America.

FOR TRAINING PURPOSES ONLY

FOR TRAINING PURPOSES ONLY

NOTICE

The material contained in this training manual is based on information

obtained from the aircraft manufacturer ’s Pilot Manuals and

Maintenance Manuals. It is to be used for familiarization and training

purposes only.

At the time of printing it contained then-current information. In the event

of conflict between data provided herein and that in publications issued

by the manufacturer or the FAA, that of the manufacturer or the FAA

shall take precedence.

We at FlightSafety want you to have the best training possible. We

welcome any suggestions you might have for improving this manual or

any other aspect of our training program.

CONTENTS

SYLLABUS

Chapter 1 AIRCRAFT GENERAL

Chapter 2 ELECTRICAL POWER SYSTEMS

Chapter 3 LIGHTING

Chapter 4 MASTER WARNING SYSTEM

Chapter 5 FUEL SYSTEM

Chapter 6 AUXILIARY POWER UNIT

Chapter 7 POWERPLANT

Chapter 8 FIRE PROTECTION

Chapter 9 PNEUMATICS

Chapter 10 ICE AND RAIN PROTECTION

Chapter 11 AIR CONDITIONING

Chapter 12 PRESSURIZATION

Chapter 13 HYDRAULIC POWER SYSTEMS

Chapter 14 LANDING GEAR AND BRAKES

Chapter 15 FLIGHT CONTROLS

Chapter 16 AVIONICS

Chapter 17 MISCELLANEOUS SYSTEMS

WALKAROUND

APPENDIX

ANNUNCIATOR PANEL

INSTRUMENT PANEL POSTER

MODIFYING YOUR PTM VOLUME 2

Please note that the Challenger Model CL-600-2B16 Pilot Training Manual Volume 2 includes

a compilation of both the CL 601-3A and CL 601-3R.

Where information is standard for both models, the footer shall denote CL 601-3A/R. If information

is specific to one model the footer shall read CL 601-3A or CL 601-3R as appropriate.

The following chapters are specifically affected by differences between models, please take the

indicated actions to make your manual correspond to the model of your aircraft:

Chapters Affected Action

Chapter 2—Electrical Pages 2-21 through 2-29

Discard Appropriate Pages

Chapter 5—Fuel System Discard Appropriate Pages

Chapter 7—Powerplant Discard Appropriate Pages

Chapter 9—Pneumatics Discard Appropriate Pages

Chapter 11—Air Conditioning Discard Appropriate Pages

Chapter 12—Pressurization Discard Appropriate Pages

Annunciator Panel Discard Appropriate Pages

CL 601-3A/R SYL-i

SYLLABUS

CONTENTS

Page

COURSE INFORMATION ............................................................................................... SYL-1

Learning Center Information ...................................................................................... SYL-1

Description of Training Facility ................................................................................. SYL-1

Type of Aircraft .......................................................................................................... SYL-7

Category of Training .................................................................................................. SYL-7

Duty Position .............................................................................................................. SYL-7

Curriculum Title ......................................................................................................... SYL-7

Curriculum Prerequisites ............................................................................................ SYL-7

Course Objectives .................................................................................................... SYL-10

Tr aining Schedule (Typical) ..................................................................................... SYL-10

Simulator and Flight Training .................................................................................. SYL-13

Completion Standards .............................................................................................. SYL-13

AIRCRAFT GROUND TRAINING CURRICULUM SEGMENT ................................ SYL-14

Curriculum Segment Outline ................................................................................... SYL-14

Tr aining Module Outlines ........................................................................................ SYL-15

FOR TRAINING PURPOSES ONLY

FlightSafety Canada

Ltée

Ltd.

CL-600-2B16 PILOT TRAINING MANUAL

FLIGHT TRAINING CURRICULUM SEGMENT ....................................................... SYL-21

Tr aining Hours ......................................................................................................... SYL-21

Flight Training Module Outlines ............................................................................. SYL-21

Completion Standards .............................................................................................. SYL-25

FlightSafety Canada

Ltée

Ltd.

CL-600-2B16 PILOT TRAINING MANUAL

SYL-ii CL 601-3A/R

FOR TRAINING PURPOSES ONLY

CL 601-3A/R SYL-iii

ILLUSTRATIONS

Figure Title Page

SYL-1 Montreal Facility Floor Plan ............................................................................... SYL-2

SYL-2 Houston Facility Floor Plan ................................................................................ SYL-3

SYL-3 Tucson Facility Floor Plan .................................................................................. SYL-5

FOR TRAINING PURPOSES ONLY

FlightSafety Canada

Ltée

Ltd.

CL-600-2B16 PILOT TRAINING MANUAL

SYLLABUS

COURSE INFORMATION

LEARNING CENTER INFORMATION

FlightSafety International is an aviation training company that provides type-specific training

programs for over 50 different models of aircraft, using a fleet of over 150 simulators. FlightSafety

operates 38 Learning Centers, including Centers in Europe and Canada.

Tr aining for the Challenger series aircraft is conducted at the Montreal Learning Center in Dorval,

Quebec, Canada, the Houston Learning Center in Houston, Texas, and the Tucson Learning Center

in Tucson, Arizona. The Centers are owned and operated by FlightSafety International.

Listed below are the addresses of the three Centers:

FlightSafety Canada Ltd FlightSafety International

Montreal Learning Center Houston Learning Center

9555 Ryan Avenue 7525 Fauna at Airport Boulevard

Dorval, Quebec, Canada H9P 1A2 Houston, Texas 77601

FlightSafety International

Tucson International Airport

1071 E. Aero Park Blvd.

Tucson, AZ 85706

DESCRIPTION OF TRAINING FACILITY

Each classroom and briefing room is adequately heated, lighted, and ventilated to conform to

local building, sanitation, and health codes. The building construction prevents any distractions

from instruction conducted in other rooms or by flight operations and maintenance operations

on the airport.

Classrooms are equipped for presentation of 35mm slides by front- or rear-screen projection,

controlled from a lectern. A standard overhead projector is available for use in the classroom.

Some overhead projectors are equipped with computer graphic animated motion for displaying

schematics and diagrams. Cockpit panel posters and/or cockpit mockups are also available at

most locations.

Briefing rooms are equipped with cockpit panel posters, a white liquid chalkboard, a table, and

chairs for individual or small-group briefings. Floor plans of the Montreal, Houston and Tuscon

Learning Centers follow.

FlightSafety Canada

Ltée

Ltd.

CL-600-2B16 PILOT TRAINING MANUAL

CL 601-3A/R SYL-1

FOR TRAINING PURPOSES ONLY

Prévia do material em texto